Split Sheath Cartridge Heaters - The very adjustable and fast extraction system

Our Enhancements & Improvements compared to older Watt-Flex Style Split Sheath Cartridge Heaters are because ours have;

- More & Thicker Wire, making it very Robust & Long Lasting due to its Heating Coil being physically stronger

- A built in Thermocouple giving better accuracy & sensitivity to its ambient temperature changes and therefore avoiding overheating

- Our Wide Variety of Lead Wires are more Securely connected within the Heating Cartridge

- Our modernised Watt-Flex style Cartridge heats along its entire length for better & an improved heat transfer

- Both standard sizes or customised versions to your specifications available

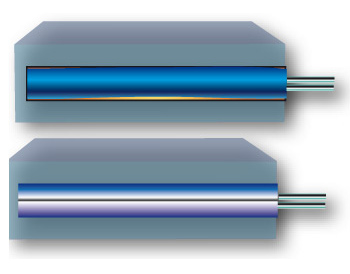

Our Advanced Watt-Flex Style Split Sheath Cartridge Heater Compared to Conventional Heater Cartridges

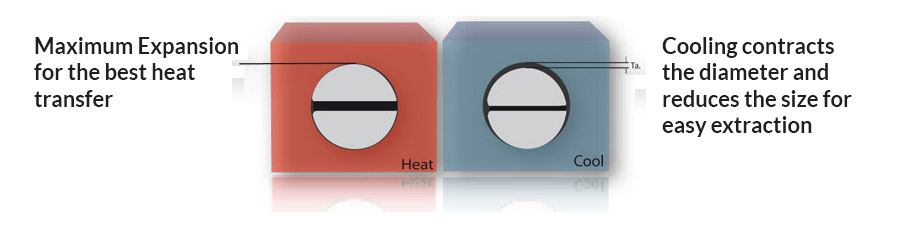

- Our Heaters expand to fit the hole, helpful in larger holes & those that are a loose fit due to wear are tear or drilled out holes

- Supports Faster & Easier Extraction, as our Split Sheath Cartridges close together when cool, reducing the diameter & loosening the fit within the hole. So no need for drilling out the cartridge or using lubricants. Saves a lot of time & effort.

- Allows trouble free use in longer holes, as the split sheath design increases the cartridges rigidity , so prevent bending therefore keeping a flatter profile enabling a better fit.

- Due to the split sheath expanding & contracting its diameter, there is no need worry about tight tolerances i.e. a loose fitting or drilled out hole.

The heater that fits the hole.

When heat is applied, the two domed arms of the tong shaped heater move outwards to the surrounding holes walls to create a very close fit. This maximizes surface area contact along its length greatly improving the heat transfer, while also prolonging the life of the heater as it prevents overheating sections forming hot spots due to air gaps may occur.

When the cartridge cools the arms retract to their original diameter, reducing the fitting tolerances for easier removal. This saves time and money reducing your overall maintenance budget, including interruption to production and repair of the bore etc.

Made For Longer Lengths

Our Bifurcated design ensures a much more rigid flatter sheath combination, with the two semi-cylinders supporting each other. So the split sheath do not bend like a conventional heater, which can bow with the heat, creating air gaps in the middle section, which causes Overheating that leads to the heating wires insulation failure. Also the bent conventional cartridge is then very difficult to extract seizing it in the bore.

Fast & Easier Insertion & Extraction, even with Long Cartridges

Our Split Sheath Heaters expand when heated & contract when cool allowing easy and quick removal. So no lubricants (which can damage the cartridges ceramic plug & lead wires) are required, nor any drilling out of the used cartridge to remove it. Another advantage is that you can easily swap split sheath cartridges into other tools, lowering your stock requirements.

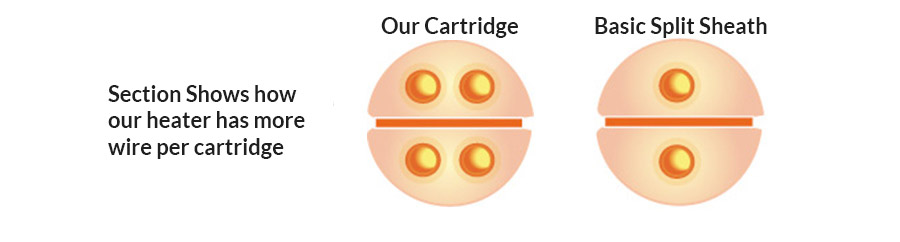

The Big Difference – Our Cartridges Longer Life & Better Performance

There is much more heating coil wire in our expandable heaters (see picture) than in any other equivalent split sheath or conventional cartridge heaters. With more heating wire you can use a larger diameter wire for the same amount of Watts used. Which reduces the physical and electrical degradation of the coil, dielectric powder, & wire connections . This extends our cartridges life by more than 4 times as long , versus a conventional heater.

Our Cartridges better fit maximises the surface area contact with the bores wall, improving the heat transfer. So a lot less power is needed to achieve the required tool temperature, reducing your operating costs for energy, component replacement, maintenance time and production continuity.

Our heaters provide like new performance, and long lasting trouble free operation.

Patent pending

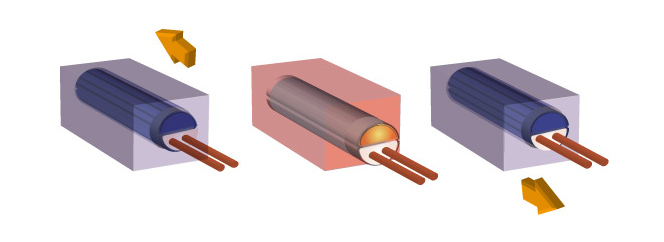

How our Split Sheath System is Engineered

Our Expandable Heater is a highly compressed cartridge, which heats the tool rapidly and evenly. These are made with the best possible materials , including Finely Powdered Mg02 Di-electric Powder, Nickel Chrome 80/20 Heating Wire and Swaged stainless steel sheaths, assembled in a highly automated ISO 9001 Quality Controlled Production System.

One of the most important processes is the precise bending of the hinge section of the semi-spherical cartridge arms, into the tong shaped form. Resulting in a very durable sprung hinge that allows for the repeated expansion and contraction of the heater.

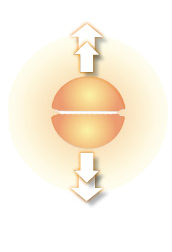

In the expansion process - When energised the Cartridge’s metal heats and expands at the hinge end, widening the distance between the twin arms pressing these into the bore holes walls.

At the contraction process - After it is de-energised the split sheath cools and the metal contracts , pulling the two arms together at its pivotal point into its original configuration and diameter.

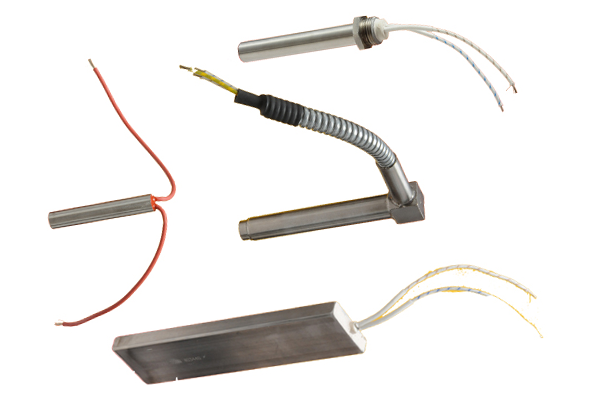

Hundreds of different Ending Options

We have all the possible endings you may require, including sealing for water/fluid resistant versions and those that can compensate for continuous Abrasion, Movement & Vibration, also with those that can withstand Very High Temperatures, Corrosive and Saline environments.

Internal Thermocouples for the Best Control

Our Expanding Heaters, like our conventional cartridges, can be made with a range of internal thermocouple sensors including J , K and PT100 types. There are several advantages of including sensors internally, for instance extending the life of the cartridge by avoiding overheating , improved accuracy with localised temperature control which also saves energy and is extremely useful when there are space limitations, preventing the proper placing of a conventional thermocouple.

A More Uniform heating

The Expandable Heaters are made with just one heating wire, it's coil is shaped so that it has a much greater quantity of wire than any other model of cartridge heater. We obtain through this a uniform heating through the whole perimeter, without any cold areas or temperature variations.

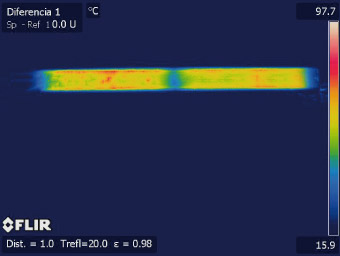

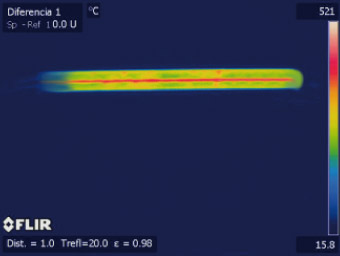

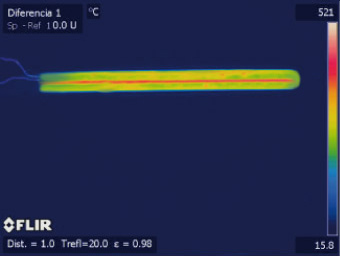

The pictures below are a comparison of our expandable range against other competitors similar products.

Conventional High Compression Cartridge

Shown in the thermal image above are several cool zones , especially in the centre and at both of its ends. This results in a much reduced and more uneven heat transfer.

The Outmoded Split Sheath Cartridge’s

The Thermal image shows a colder section at its connection end, so still does not uniformly apply an even heat over its complete length.

Our Advanced Expanding Heater’s

The Thermal image shows an even spread of heat throughout due to its modern design and improved construction techniques, this allows more heat through its entire length.

Thereby giving the best possible spread and the most effective heat transfer, so it requires less energy to reach the required temperature and also heats the system more quickly.

As well as the standards sizes below , any dimension or specification between these can be supplied in imperial and/or metric equivalents. Including the diameter, length, voltage, wattage (including compound wound)mountings, lead wires and sleeves.

| Ø | Drill | Actual Ø | Cold zone | Minimum length |

Maximum length |

Maximum amps according to the length |

|

| 3/8'' | 9,52 ±0,1 | 9,3 | 20 | 100 | 1000 | 15 | 15 |

| 10 | 10 ±0,1 | 9,8 | 20 | 100 | 1000 | 15 | 15 |

| 12 | 12 ±0,1 | 11,8 | 20 | 100 | 1500 | 25 | 25 |

| 12.5 | 12.5 ±0,1 | 12,3 | 20 | 100 | 1500 | 30 | 25 |

| 1/2" | 12.7 ±0,1 | 12,5 | 20 | 100 | 1500 | 30 | 25 |

| 15 | 15 ±0,1 | 14,8 | 30 | 100 | 1500 | 40 | 25 |

| 5/8'' | 15,88 ±0,1 | 15,68 | 30 | 100 | 1500 | 40 | 25 |

| 16 | 16 ±0,1 | 15,8 | 30 | 100 | 1500 | 40 | 25 |

| 3/4'' | 19,05 ±0,1 | 18,85 | 30 | 100 | 1500 | 40 | 25 |

| 20 | 20 ±0,1 | 19,8 | 30 | 100 | 1500 | 40 | 25 |

| 25 | 25 ±0,1 | 24,6 | 30 | 100 | 1500 | 40 | 30 |

| 1" | 25,4 ±0,1 | 25 | 30 | 100 | 1500 | 40 | 30 |

| Voltage (V) |

120 - 130 - 240 - 380 - 400 |

| Power tolerance(w)* | +5% to -10% |

| Power | Depends on the dimension |

| Length Tolerance | ± 3% maximum 20mm |

| Standard Diameter's Tolerance | -0.10 to -0.15 mm |

| Leakage current* | <=0.5mA a 253 v. |

| Insulation* | >=5 MΩ a 500 V |

| High voltage heaters* | 1500V to > 24V Operating voltage |

| 500V to > 24V Operating voltage | |

| Tube material | Stainless Steel |

| Wire | NiCr 8020 |

| Melting temperature | 750º C |

*tests have been done at room temperatures

Enquiry Form

Complete our enquiry form or alternatively email us direct as sales@lojerproducts.co.uk or call 01635 865882